- Accurate costing

- Eliminate job packets

- Multi-year double digit revenue and profit growth with fewer staff, no inventory increases, no additional outsourcing, no facility or machinery changes

- Greater throughput

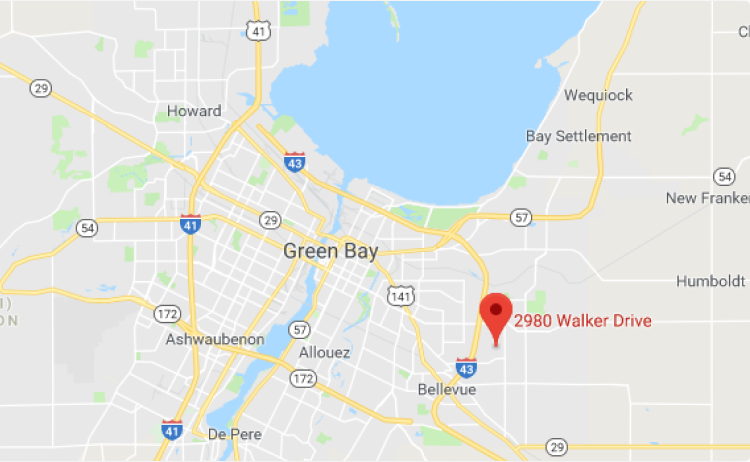

Beacon-Trak™: Beacon Technology for Manufacturers

Beacon-Trak™ combines innovation and technology to revolutionize the way shop floor supervisors manage production. Beacon-Trak™ for SyteLine ERP is a patent-pending product that brings relevant, proximity-based information to a supervisor as they walk the shop floor and interact with their associates.

Features

Be aware of what’s happening on the shop floor in the moment

Provide supervisors with specific details without searching

Real-Time Dashboard

Role-Based Roadmap

Benefits

In manufacturing, there’s so much happening on the shop floor at any given point that it’s almost humanly impossible to keep up with every detail. Supervisors are too bogged down trying to navigate insufficient or out-of-date information to work as closely as they need to with associates in order to increase production, improve quality, and lower costs. That’s where Beacon-Trak™ comes in.

- Arrange the 3” x 3” Bluetooth-enabled beacons around your shop floor, and leverage the accompanying tablet computer to put instant, dynamic information in the hands of shop floor supervisors.

- Equip supervisors to better manage their work, quality, staff, and equipment.

- Benefit from real-time data on all of your work centers without having to search – supervisors can see at a glance who is working, what their jobs are, what machines are being used, what the productivity and job status is, and more.

- Gain critical insight into individual, departmental, and work center performance with seven-day running charts.

- Use Quick Links to instantly access job details, analytics to observe trends, quality information, reject rates, efficiency details, and more.

- Take a virtual walk around the shop floor by selecting the beacons from a map of your work areas.

- Manage conference room meeting discussions by knowing what is happening in real-time.

- Put the dashboard into roaming mode and walk the shop floor, or shut it off and see everything.

- Leverage one set of beacons to assist multiple roles: quality, setup, human resources, cost accounting, machine maintenance, overall equipment effectiveness (OEE), executive management, planning/scheduling, customer service, inventory management.

Industries

Beacon-Trak™ is used in multiple industries to streamline manufacturing processes:

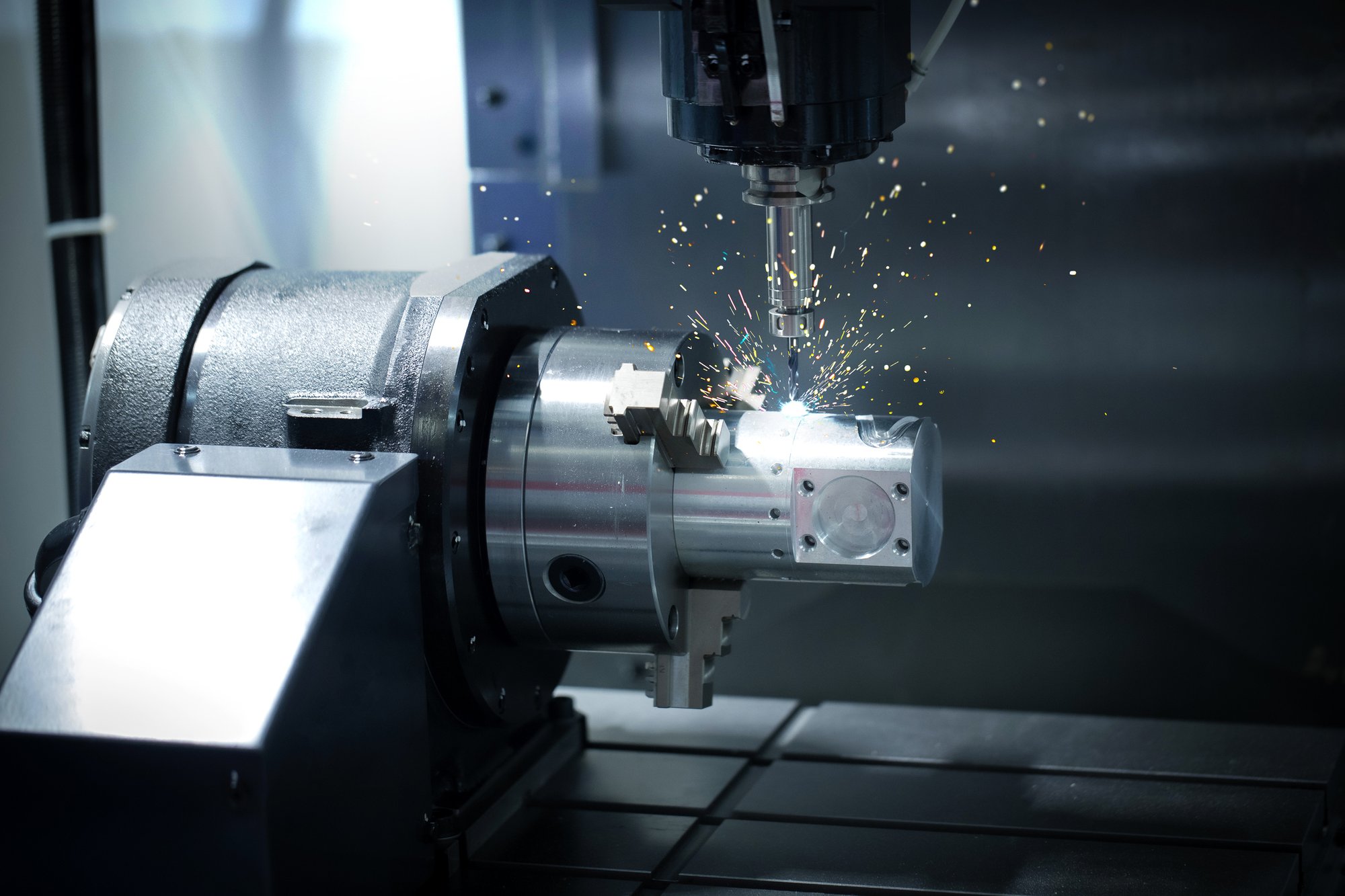

Industrial Machinery

Metal Fabrication

Contract and Precision Matching

Aerospace

Defense and Medical Equipment

- Greater quality

- Shorter lead-time

- Exceed previous maximum output

- Increase people and machinery efficiency and utilization

- Automated DoD/IP document security

- Greater worker acceptance

- Shorter lead-time

- Simplicity built in

- Reduced training requirements

- Better data for better reporting and analysis

- Documented procedures to maintain consistency and reduce onboarding cost/time

- Grow revenue while flatlining or reducing operational and inventory costs

- Monitor back-office efficiency and ability to handle growth

- Methodology to find and resolve operational obstacles throughout the organization

- Manage cross-location sourcing of parts and assemblies

Supported Roles

Beacon-Trak™ supports users across your entire manufacturing enterprise:

- Easier, accurate product costing

- Confidence in balance sheet, inventory, account balances

- Reduce overhead allocations through greater utilization of people and machinery

- Quickly make a delivery promise with confidence it will be met

- Fewer customer interruptions

- Rapid order tracking, including in the shop

- Unique document delivery processing with no baby-sitting the process

- Accurate inventory

- Uniquely designed cycle counting process

- Lot/Serial tracking

- Optimized operating procedures specific to the need

- High speed processing

- Middle-of-the-day processing to respond to new orders

- Accurate and real-time partial and full work completions

- Statistical analysis of utilizations and efficiencies to improve work scheduling and material requirements

- Optimized operating procedures specific to the need

- Purchasing

- Job Costing

- Work Dispatching

- Service & Repair

.png?width=97&height=97&name=TrakSuite_logo_white_transparent%20(1).png)