- Accurate costing

- Eliminate job packets

- Multi-year double digit revenue and profit growth with fewer staff, no inventory increases, no additional outsourcing, no facility or machinery changes

- Greater throughput

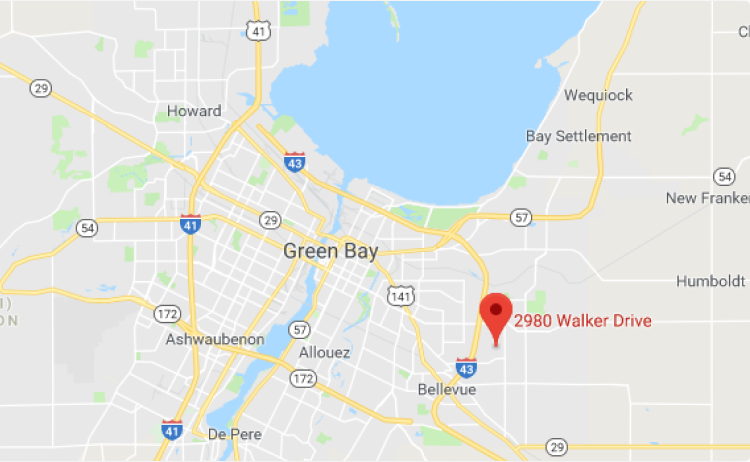

APS Made Easier: Synchronize Inventory and Production with Demand

APS Made Easier is a training program that helps manufacturers optimize inventory, material sourcing, and production scheduling, allowing you to promise accurate delivery dates and enhance customer satisfaction.

Features

Keep inventory low while avoiding shortages

Improved Efficiency

Production Aligned with Demand

Seamless Advanced Planning Capabilities

Benefits

Organizations sometimes waste money by carrying too much inventory, while carrying too little can result in lost sales or late shipments. To reach lean manufacturing goals within your company, you need lean planning capabilities – and you need to align your planning with execution on the shop floor. That’s where APS Made Easier comes in.

- Automate the process of calculating and monitoring your inventory drivers, including forecasts, safety stocks, and order size.

- Accurately size your inventory in make-to-stock and make-to-order environments by forecasting sellable items or components.

- Easily locate, reserve, and buy supplies and materials from multiple locations, vendors, customers, and company sites.

- Focus your planning on customer demand, pulling to the customer due date and synchronizing the flow of material and capacity accordingly.

- Automatically plan and schedules materials, production, and capacity order-by-order, eliminating lag times in the planning process and delays in customer order delivery.

- Drive shop floor execution with dynamic, real-time electronic work center dispatch information that your supervisors can manage to get the most out of your people, machinery and facilities.

- Increase efficiency, feedback, and visibility in a proactive process with shop floor touchscreen reporting that continuously updates production information.

- Benefit from simultaneous materials & and resource scheduling and what-if capabilities to determine the impact of decisions.

- Enable real-time promise dates at the time of order entry that consider the constraints of both material and capacity.

Industries

APS Made Easier is used in multiple industries to streamline manufacturing processes:

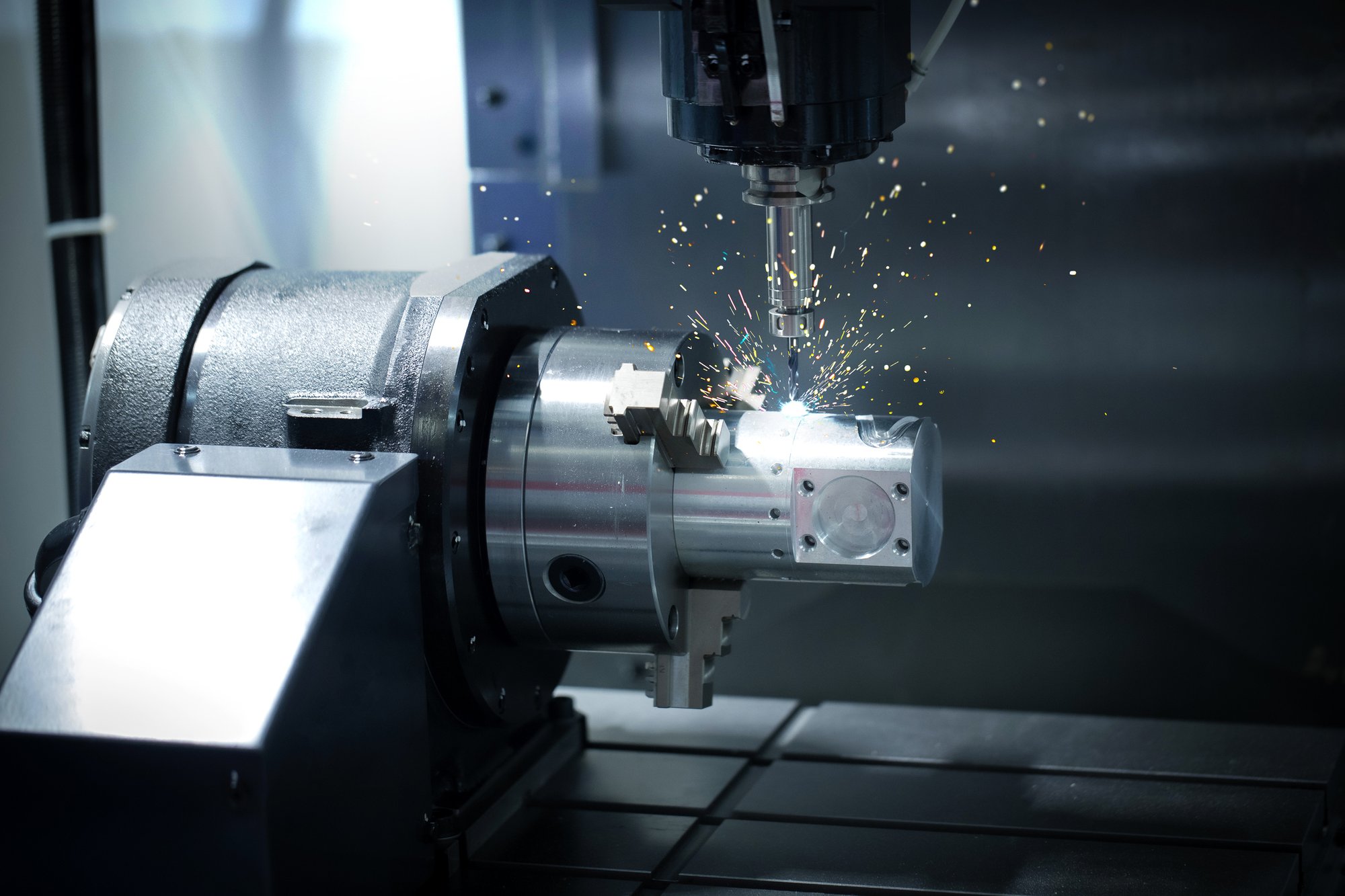

Industrial Machinery

Metal Fabrication

Contract and Precision Matching

Aerospace

Defense and Medical Equipment

- Greater quality

- Shorter lead-time

- Exceed previous maximum output

- Increase people and machinery efficiency and utilization

- Automated DoD/IP document security

- Greater worker acceptance

- Shorter lead-time

- Simplicity built-in

- Reduced training requirements

- Better data for better reporting and analysis

- Documented procedures to maintain consistency and reduce onboarding cost/time

- Grow revenue while flatlining or reducing operational and inventory costs

- Monitor back-office efficiency and ability to handle growth

- Methodology to find and resolve operational obstacles throughout the organization

- Manage cross-location sourcing of parts and assemblies

Supported Roles

APS Made Easier supports users across your entire manufacturing enterprise:

- Easier, accurate product costing

- Confidence in the balance sheet, inventory, account balances

- Reduce overhead allocations through greater utilization of people and machinery

- Quickly make a delivery promise with confidence it will be met

- Fewer customer interruptions

- Rapid order tracking, including in the shop

- Unique document delivery processing with no baby-sitting the process

- Accurate inventory

- Uniquely designed cycle counting process

- Lot/Serial tracking

- Optimized operating procedures specific to the need

- High speed processing

- Middle-of-the-day processing to respond to new orders

- Accurate and real-time partial and full work completions

- Statistical analysis of utilizations and efficiencies to improve work scheduling and material requirements

- Optimized operating procedures specific to the need

- Purchasing

- Job Costing

- Work Dispatching

- Service & Repair

.png?width=97&height=97&name=TrakSuite_logo_white_transparent%20(1).png)